ANNOUNCEMENTS

HAND-OVER

- My

name is _____________.

- To register,

please Queue-Up.

- Keep

ready

- Your

Interview-Call letter

- Extra-copy

of your Bio-Data.

- One

copy of your photo. Please staple this photo to left hand top

corner of your Bio-data. You will find a stapler on the side table here (point

out)

- Make

Sure to write your PEN (Permanent Executive Number) on the right

hand top corner of the bio-data in bold letters

- On

the side table here (point-out) you will also find

- WELCOME

FOLDERS

- After

you have registered with me please pick-up one folder.

- The

folder contains an Identity Badge.

- Please

write your NAME and your PEN on the ID Badge. Also

insert the Second copy of your photo Inside the ID Badge

here (points out by holding high).

- Always

write your NAME in bold CAPITAL letters – no matter where. PEN

must also be written in LARGE NUMBERS.

- Once

your ID Badge is ready, please wear it on your shirt-pocket

like this (demonstrate).

- You

must wear this ID Badge as long as you are on the hotel premises.

- In

the evening when you leave, you must return the ID Badge to me.

This is important.

- On

the WELCOME FOLDER, there is a small flap containing a small white

card.

- Write

your NAME & PEN on this card & re-insert. This will

ensure that even if you misplace your folder, it will be returned to you.

- "Welcome-Folder"

contains a booklet titled MAY WE KNOW YOU PROFESSIONALLY? (Hold-up

one booklet to show)

- While

you are waiting to be called for the interview, please fill-in this

booklet.

- Before

you start to answer the questions, make sure to enter your NAME/PEN

etc. on first page here (Hold-up and show).

- When

you have finished, keep it with you in the folder and carry with you to

the Interview Room where, please hand it over to the Interviewer.

- If,

for any reason, you have not been able to complete this questionnaire by

the time, you are called for the interview, you may finish it later after

the interview. In such a case, please handover this questionnaire to me

before leaving. This is very important since "this

questionnaire forms a crucial input" to your assessment.

INTERVIEWS

- There

are 4 rooms on the 5th floor where the interviews are being

conducted. These are Room Nos.

- When

the interview is over, the interviewer will seal the brown envelope and

hand it back to you. Do not open. As soon as you come out of the Interview

Room, please hand-over the brown envelope to the Coordinator, Mr.

_____________. This is absolutely a "must".

- When

you finish the interview, please come back and wait in the Senate Room.

Do not loiter in any other areas of the hotel.

- The

outcome/result of the preliminary interview will be communicated to you

in the afternoon at about 4 p.m.

- Those

of you who have given the interview in the morning (M Batch) will

go to the terrace in the afternoon by 2:00 p.m. to take

psychometric test, which will start at 2:30 p.m. and take about 1

$\frac{1}{2}$ hours.

- So

preliminary interview results of the morning batch (Batch M) will

be announced in the terrace by the Co-ordinator who is sitting

there.

- In a

converse manner, those who have taken their psychometric test in the

morning at 9:30 am. (i.e. Batch A Candidates), will return to the Senate

Room (after their lunch) at 1:30 p.m. for their interview.

- Their

interview-results will be announced by the Coordinator sitting in the

Senate-room at about 6 p.m.

FINAL INTERVIEW

- Those

of you who get short-listed in the preliminary interviews to-day,

will be required to come back tomorrow morning at 8:30 A.M

- These

candidates will undergo some more tests followed by final interview by the

Managers of OWENS-CORNING.

Tea/Snack Coupons

- Your

welcome folder contains two tea coupons and a Snack coupon. Hotel

management will serve the tea in the morning and in the afternoon,

wherever you happen to be seated.

- For

snacks, you will need to go to the fast-food restaurant "Ganga",

situated on the ground-floor, next to the gate through which you entered.

You will need to surrender the snack coupon there, which is valued

for a sum of Rs. 20.

- If

you order a more expensive item, you will need to pay the difference in

cash.

- To

avoid crowding in the restaurant, please visit it anytime between 12:00

noon and 1:30 p.m (anytime after your interview If you are in the

Morning Batch).

- As

far as AFTERNOON BATCH is concerned, they will be free as soon as

their psychometric test is over in the morning, say around 11 am.

onwards. So they can have their snack anytime between 11 am & 1:30

p.m.

Xerox Copies of Certificates/Salary-slip etc.

- For

the time-being, please keep these with you.

- We

will need to verify these only for those candidates who get "short-listed"

in the preliminary interview.

- If

you are declared to have been short-listed, please bring to me your

original as well as Xerox copies for verification. I will

return to you your ORIGINALS after Verification. Please do not

forget to collect your originals before leaving. This is very

important. If you forget, we cannot take responsibility for this.

Travel-Reimbursement

- My

colleague, Mr. Kamlesh will reimburse travel expenses to outstation

candidates at – 4 $\frac{1}{2}$ p.m. in Terrace – 5 p.m. in Senate Room

Decorum

- While

you are here, please conduct yourself with dignity befitting future

executives of OWENS-CORNING.

- Most

certainly do not disturb others who are busy filling-in their "MAY

WE KNOW YOU" questionnaire.

- If

there is any question now, please feel free to ask, and I will be

happy to answer. Once others have started filling the Questionnaire, do

not ask your question loudly so that others may not get disturbed.

However feel free to walk-down to me to clarify your doubts.

Keeping Busy

Once you have completed the Questionnaire, you may wish to

keep yourself busy

- by watching

TV which shows some product/process details of OWENS

- by studying

OWENS literature kept in your welcome folder

- by reading

newspapers/magazines

I WISH you all a very lucky day!

Dear Sir:

We are happy to welcome you to this interview and thank you

for making it despite a short notice.

Please carefully read the following:

- Now

you have registered yourself and got this folder and your Identity

Badge. Of the 2 copies of your photograph (which you are

supposed to have brought with you), please insert one copy into the ID

Badge and wear this Badge on your shirt-pocket as long as you are at the

interview premises.

- Please

handover to our CO-ORDINATOR

- 2nd

copy of your photograph

- a

copy of your resume (biodata)

- photocopies

of your Certificates for Verification

- To-day's

program consists of

- a

preliminary interview

- some

written tests

For the written tests, there will be

TWO batches as follows:

- Morning

Test Batch at 9:30 A.M. (Location: Terrace, 6th Floor)

- Afternoon

Test Batch at 2:30 P.M. (Location: Terrace, 6th Floor)

The test will last approx. 1 hour and will be

conducted on the 6th floor.

Our Co-ORDINATOR will announce whether you belong to

the MORNING BATCH or the AFTERNOON BATCH.

MORNING TEST BATCH

Those of you who are in the MORNING TEST BATCH can expect to

be free by 11 A.M., after which you may leave the premises (if you wish) and

return to this room latest by 1:30 PM after taking your lunch. Your preliminary

interviews will commence at 2 P.M.

AFTERNOON TEST BATCH

Those of you who are in the AFTERNOON TEST BATCH, should

continue to sit in this room throughout the morning. Your preliminary

interviews will be held during the morning. After your interview, you may go

out, have your lunch and return latest by 1:30 p.m. to undergo your test which

will commence by 2:30 p.m.

- FINAL

INTERVIEW

The final interviews will be conducted by the executives of OWENS-CORNING

(I) LTD. These will be held to-morrow.

Those of you who get short-listed for the FINAL interview

will be informed accordingly by our CO-ORDINATOR. For such short-listed

candidates, there will be some more written tests tomorrow.

If you are informed that you have been short-listed, you

must report in this room tomorrow morning at 8:00 AM.

At the end of the final interview tomorrow, if you get

selected for appointment, you will be issued an APPOINTMENT LETTER

tomorrow itself. In such an event you will be required to sign and return the

duplicate copy of the Appointment Letter, by way of your "acceptance,"

before you leave this premises.

Successful candidates (the appointees) will be expected to join

duty at OCIL TALOJA PLANT on 5th March 1998. If they do not possess a

passport, they should get one ready by that date.

- ID

BADGES

These must be returned to our CO-ORDINATOR at the end of

each day before you leave the premises.

- TRAVEL

EXPENSE RE-IMBURSEMENT

Outstation candidates will be reimbursed II class return

trainfare (or bus fare), between 4 pm – 6 p.m., only after they have undergone

their preliminary interview.

- OVERNIGHT

STAY RE-IMBURSEMENT

If you are an "outstation" candidate and required

to stay overnight to appear for your final interview tomorrow, you will be

reimbursed a fixed sum of Rs. _________. You may claim this after completion of

your final interview tomorrow.

Mr. Dave S.T.

Mr. Vaishnava - Baroda

Mr. Mehta - Mumbai

Many thanks for accepting our invitation to be an Interview

Panel Member at the forth-coming Interviews for our client OWENS-CORNING

(INDIA) LTD.

I enclose a copy of the advt. You will notice that:

- There

are FOUR types of positions

- Diploma

Engineers with 3/5 years of exp. are required

- They

will be "hands-on", shop-floor plant operators, working

in shifts.

- Almost

all will undergo 15 days intensive training at OWENS-CORNING PLANTS in

Europe/USA, between 15/2/98 – 1/4/98.

- They

will form part of "Self-directed Team" (SDT) where

there will NOT be any "functional compartmentalisation.

In rotation, each team member will be responsible for Production/Quality/Cost/Maintenance/House

keeping/Safety etc. The rotation itself will be decided by each team

without any interference from Managers! There will be team-accountability.

So, attitude & TEAM-WORKING is crucial. LONERS / LONG-WOLFS

are not acceptable!

Owens want to fill about 50 vacancies, which are

approximately distributed as follows:

- Process

Personnel __________ 20/25

- Maint.

___________________ 8/10

- Batch/Furnace

" ___________ 8/10

- Chemical

" ________________ 8/10

For Owens, to be able to select 50 candidates (in

their final interviews), we need to put-up before them, about 100 candidates

at the end of Preliminary Interviews (which is our responsibility). We are not

required to participate in the final interviews (which will be going on

concurrently, starting from 22/2 i.e. 2nd day.)

For us, to be able to "short-list" 100

Candidates, we need to interview between 400-500 Candidates, over a

period of 6 days (i.e. 21st Feb – 26th Feb – although advt. says

20th Feb.)

This means, we need to interview, between 65-80

candidates per day, which will amount to 16-20 candidates per day for

each of you.

We plan to start the interviews at 9:00 am at

intervals of 30 minutes, with a 45 minute lunch-break at 1:00 p.m.

OWENS have also appointed another Agency to

conduct PSYCHOMETRIC TESTS on all the candidates called by us for

prelim. interview. These tests will be spread over 2 days.

On the Prelim. Interview day

Agency (BRISC) will give test to 40 guys in the morning

& 40 guys in the afternoon.

When "morning" batch is taking the test, we

(our 4 panels) will conduct prelim. interviews of the "afternoon"

batch. After lunch, the process will be reversed.

On/From Second day onwards

Only those candidates who have been "short-listed"

by our Panels, at the end of the day, will be called again on the following day

(8:00 am), to

- undertake

further "personality" tests

- undergo

final interview (by Owens Managers).

At the end of each (Candidate's) prelim. Interview, you will

directly, on the spot (before he leaves interview-room) inform him

whether he is short-listed for FINAL interview or not. If yes, ask him

to report again next morning at 8:00 am.

Prelim. Interview Rating

For each candidate, at the end of the interview, you will

fill-in, enclosed PRELIMINARY INTERVIEW EVALUATION SHEET.

You will also give each candidate, an "OVERALL

SCORE" as:

- A

= Excellent

- B

= Good

- C

= Acceptable

- R

= Reject (R1 - first time reject)

All those candidates who get overall score of A, or B, or

C, shall be asked to come next morning (8:00 am) for FINAL interview.

BRISC (Agency) will directly hand-over to OWENS

Managers present, their findings of Psychometric Tests.

Decision, whether or not to call a candidate for FINAL

interview is solely OWENS and must be based on our evaluation of the

candidate's Technical / Job knowledge and Experience Relevance.

ASSESSMENT OF JOB-KNOWLEDGE

This will be done by

- getting

each candidate to fill-in a "May We Know You Professionally?"

questionnaire (a sample enclosed)

- Interview-process

itself.

- In

this connection, please see my enclosed

- Notes/Points/Questions

(1 page)

- Interview

Notes (12 pages)

In "Interview Notes," I have jotted-down

some questions at random. It is really a mix-up of

- "May

We Know You Professionally"

- Question

Databank

This is a request to Baroda-based EXPERTS (Interview

Panel Members) to spend sometime together and divide these random

questions into 2 distinct documents as mentioned above and return to me

both by 18th Feb. Please feel free to ADD/DELETE/MODIFY.

As far as "May We Know You Professionally"

is concerned, I need to computerise and take out 500 xerox copies and keep

ready by 20th Feb.

For Question Databank (Please divide this in distinct

SECTIONS and assign DEGREE OF DIFFICULTY), we need to make only 4/5

copies.

Looking forward to meet you on 20th.

Regards

[Signature]

8/2/98

cc: Mr. P.K. Mukherjee

Programme Director (OWENS ASSIGNMENT)

We would like to prepare

|

"May-We-Know-You Professionally?" Document |

"Question-Bank" Document |

|

* To be handed-over to candidates as they walk-in

& ask them to fill-in when they are waiting. |

* This is an "internal" document to be

used by Interviewers as an "aide". |

|

* This will keep them occupied & reduce

talking/commotion. |

* This should be separate for Maint. people. |

|

* This should be Objective type |

* Taking into account that candidates are

Diploma-Engineers with 3/5 years of experience, each question must be

assigned "DEGREE OF DIFFICULTY". |

|

* Yes (NO: $\checkmark$) |

* Number of questions asked of a candidate must be

equally distributed amongst various "DEGREES". |

|

* True/False |

* Each candidate must be asked some no. of

questions under each "DEGREES". |

|

* Multiple-choice |

* Total questions must be same for all. |

|

* Should be Separate for MAINTENANCE-Guys. |

|

|

* This should be given in the "morning"

to "Morning" candidates "afternoon" to

"Afternoon" |

OWENS-CORNING

INTERVIEW NOTES

1. What are typical Process-Parameters in a

continuous process plant? How are these monitored? How are these controlled?

2. How is production (Output) maximised?

Does quality suffer if we try to "increase output"? What are

the "factors" that limit the output? What is "rated

capacity"? What are "bottlenecks"? How is "de-bottlenecking"

carried out?

3. Why have many process-plants to run "continuously"?

What happens when such a plant is stopped? What precautions need

to be taken before shutting-down a "continuous" process? What

needs to be done before "re-starting" such a plant? What is

the difference between a "continuous" process-plant and a

"batch-process" plant? What type of equipment/machinery do

each employ?

4. Give names of equipments which you are familiar

with:

- Static

Equipment

- Rotating

Equipment

- Maintenance

Equipment

- Utilities-related

equipment

- Instruments

5. Give examples of commonly occurring faults in each of the

above-mentioned types of equipments.

($-$ and how these can be detected and set right $-$ for

maintenance personnel).

6. In a process-plant, following factors

govern/influence the quality of the output. Please rank them in the

order of importance:

- Quality

of Raw Materials [ ]

- Control

of process-parameters [ ]

- Condition

of Machinery/Equipment [ ]

- _____________________________________________________________

[ ]

- _____________________________________________________________

[ ]

7. In a process-plant, following factors

govern/influence the Cost of the output. Please rank them in the order

of Importance:

- Cost

of input raw-materials [ ]

- Energy

Consumed per Unit of Output [ ]

- Maintenance

Cost [ ]

- Labour-Cost

[ ]

- Royalty/Technology

Knowhow Fees [ ]

8. What is the difference between "Erection"

& "Commissioning" & "Pilot Production"?

9. When does a process said to have become "stabilized"?

10. What are the most common methods for controlling

the INPUTS-RATIO?

11. What are the common "symptoms/manifestations"

of

- a process

malfunction?

- an

equipment malfunction?

12. How is "Troubleshooting" different from

"Preventive Maintenance"?

OR

Is there any difference between "Trouble-shooting"

& "Preventive Maintenance"? If yes, please describe.

13. Is there any difference between

- Preventive

Maintenance &

- Predictive

Maintenance?

14. Are there any methods of predicting an

equipment breakdown? What "records" need to be kept and

what statistical methods need to be employed for predicting an equipment

breakdown? How can you increase the "accuracy" of such predictions?

15. What is "Condition Monitoring"?

How does it influence

- Breakdown

Maintenance

- Preventive

Maintenance

- Predictive

Maintenance

16. What is the difference between

- Schematic

diagram

- Process

Flow chart

- Plant

Layout

- General

Arrangement Drawing

17. What are commonly used/found "SYMBOLS"

on a

- Mechanical

Drawing

- Electrical

Circuit Diagram

- Hydraulic

"

- Pneumatic

"

- Instrumentation

"

Explain the meaning of each Symbol.

(This question is best asked by showing to the candidate a

typical drawing/diagram of each type)

18. In a process-plant, what safety-features

are incorporated to prevent

- Pressure

Build-Up/Drop

- Temperature

Build-Up/Drop

- Runaway

Process

- Chain

Reaction

- Cooling

Water shut down/Reduction

- Clogging

of pipelines

- Emission

of Toxic gases/fluids

- Leakage

of toxic gases/fluids

- Corrosion

- Jamming

of Valves/Plugs

- Jell-ing

19. What is "Failing to Safe"

condition? How do these devices operate in relation to

- Temperature

- Pressure

- Flow

20. What are most commonly used "Insulation

Materials" found in a process-plant? Under what specific situation

is each type of material used?

What is "Thermal Gradient"?

What is "Insulation Co-efficient"?

What is "Ambient Temperature"?

Are "ceramics" ever used in a process plant?

where?

21. What are

- Air

jackets?

- Water

jackets?

Why are these used? Where ___ ____?

22. Give names of equipments to which Vibrations

are extremely detrimental.

23. How would you obtain perfect "alignment"

of

- Pipes

- Shafts

- Pulleys

- Gears

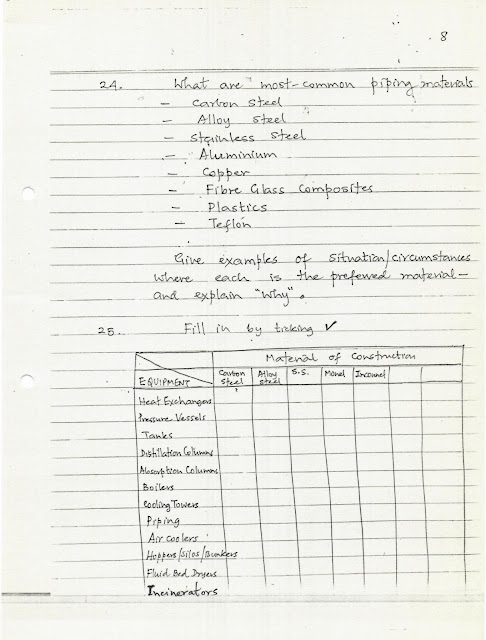

24. What are most-common piping materials

- Carbon

steel

- Alloy

steel

- Stainless

Steel

- Aluminium

- Copper

- Fibre

Glass Composites

- Plastics

- Teflon

Give examples of situation/circumstances where each is

the preferred material $-$ and explain "why"?

25. Fill in by ticking $\checkmark$

|

EQUIPMENT |

Material of Construction |

|

Carbon Steel |

|

|

Heat Exchangers |

|

|

Pressure Vessels |

|

|

Tanks |

|

|

Distillation Columns |

|

|

Absorption Columns |

|

|

Boilers |

|

|

Cooling Towers |

|

|

Piping |

|

|

Air coolers |

|

|

Hoppers/Silos/Bunkers |

|

|

Fluid Bed Dryers |

|

|

Incinerators |

26. Please expand the following abbreviations

into their full, correct expressions:

e.g. BS _____ stands for ____ British Standards

|

ASTM (AOI/MSS) |

AIEC |

|

AISI/ASM |

AIRP 2A |

|

ANS |

EURONORM |

|

UBC |

NEMA |

|

ASME |

NFPA |

|

TEMA |

ISA. |

|

UNI |

|

|

ANSI |

|

|

DIN |

|

|

API |

|

|

AFNOR |

|

|

JIS |

|

|

ISO |

27. In welding, what do the following "terms"

mean?

- SAW

- GTAW

- SMAW

- TIG

- MIG

- CITAW

28. Give examples of situations/equipments for which

the following non-destructive testing methods are employed:

- Ultrasonic

____

- Dye

Penetration ____

- Magnaflux

____

- X-Ray

____

- Eddy

Current ____

29. Give examples of situations/equipments for which

the following destructive testing methods are employed:

- Tensile

Testing ____

- Impact

"

- Creep

"

- Shear

"

- Bend

"

- Fatigue

"

30. What are following materials? & where

are they used?

- Carbon

Fibres

- Glass

Fibres

- Neoprene

- Kevlar

- Epoxy

31. What do following terms stand for?

|

HAZOP |

ABC Analysis |

|

PERT |

SQC |

|

CPM |

TQM |

|

DCS |

ISO |

|

NDT |

LAN |

|

MIS |

JIT |

|

DM Gate/Plot |

Kanban |

|

PPM |

Kaizen |

|

LPG |

Fish-bone diagram |

|

LNG |

Loop diagram |

|

CNG |

PLC |

|

CAD |

UPS |

|

CAM |

32. What do following terms mean?

- Plant

Performance Run

- Technical

Audit

- Debottlenecking

- Loss

Survey

- Condition

Monitoring

- Catalyst

Performance Status

- Safety

Audit

- Sampling

- Break-even

- Control-charts

- Standard

Deviation

- Metrology

- Environment

Audit

- Voltaic

Corrosion

- Cathodic

Protection

- Corrosion

Study

- Effluent

Quality

- Emission

Rate

- Cryogenics

- Polymer

- Annunciator

- Monitor

- Recorder

- Transducer

- Invertor

- Transmitter

- Analyser

- Plant

Load Factor

(3P EXECUTIVE SEARCH - MAINTENANCE MANAGER Questionnaire

- Page A)

A. What are "You" responsible/accountable for

in your current assignment.

|

ACTIVITY |

Tick the appropriate one |

|

COMPLETELY RESPONSIBLE |

|

|

1. Routine maintenance job in chemical industry |

$\Box$ |

|

2. Trouble shooting |

$\Box$ |

|

3. Maintenance budgeting and cost control |

$\Box$ |

|

4. Co-ordination activities of maintaining |

$\Box$ |

|

5. Maintenance record keeping/ maintaining |

$\Box$ |

|

6. Spares indenting and requisitions |

$\Box$ |

|

7. Inspection and approvals of spares / consumables |

$\Box$ |

|

8. Distribution and supervision of maintenance jobs to

various technicians |

$\Box$ |

|

9. Fabrication of pipelines |

$\Box$ |

|

10. Installation/erection of machinery and equipment |

$\Box$ |

|

11. Annual Inspection of boilers |

$\Box$ |

|

12. Conditioning monitoring, e.g. vibration analysis,

ultrasonic testing, other NDT etc. |

$\Box$ |

|

13. Manpower planning/budgeting |

$\Box$ |

|

14. Participating in committees, e.g. safety committee,

canteen committee etc. |

$\Box$ |

|

15. Appraisals of persons working under you. |

$\Box$ |

B. Job Knowledge

|

ACTIVITY |

Tick the appropriate one |

|

I AM AN EXPERT |

|

|

1. Maintenance of following |

|

|

a. Rotating machinery : Pumps, Compressors, Blowers,

Vacuum pumps, Turbines, Motors |

$\Box$ |

|

b. Reciprocating Machinery : Compressors, Pumps, Engines |

$\Box$ |

|

c. Material handling equipment : Conveyors, Elevators,

Screws |

$\Box$ |

|

d. Other equipment : Heat exchangers, Pressure vessels,

Atm. tanks, Distillation columns, Absorption columns, Boilers, Cooling

Towers/Cooling water systems, D.M. water plants/Systems, Air systems |

$\Box$ |

|

e. Materials of construction : S.S. (304, 304 L, 316, 316

L, 321 etc.), C.S., Aluminium, Glass lined/teflon/lined |

$\Box$ |

Job Knowledge

|

ACTIVITY |

Tick the appropriate one |

|

I AM AN EXPERT |

|

|

f. Types of valves : Gate, Globe, Ball, Plug, Butterfly |

$\Box$ |

|

2. Familiar with codes and standards : ASME,

TEMA, API, Indian Standards (IS 2825, IS 803 etc.), ANSI,

IBR |

$\Box$ |

|

3. Knowledge of following regulations : SMPV,

Factory act/rules, IBR, Explosive act/rules, Pollution,

ID act/rules, Standing orders, Gas cylinder rules |

$\Box$ |

Job Knowledge

|

ACTIVITY |

Tick the appropriate one |

|

HAVE USED THE TECHNIQUE |

|

|

1. A-B-C analysis |

$\Box$ |

|

2. Bar Chart |

$\Box$ |

|

3. PERT/CPM |

$\Box$ |

|

4. TQM |

$\Box$ |

|

5. Time and motion study |

$\Box$ |

|

6. Inventory control |

$\Box$ |

|

7. SWOT analysis |

$\Box$ |

|

8. ISO 9000 |

$\Box$ |

|

9. Management by objective |

$\Box$ |

The History of Owens Corning

The industrial fairs of the 19th and early 20th centuries

gave birth to innumerable revolutionary ideas and inventions that changed the

lives of millions. One of the most forward-thinking visions involved creating fibers

from glass — one of the world's oldest and most available materials.

The entrepreneurial men and women of Owens Corning's

founding companies pioneered the science of glass fiberization, creating a

dynamic organization which remains the world leader in the manufacture and

innovation of glass fiber materials.

The origin of glass fiber, and of Owens Corning, reaches

back to the glass milk and soda bottle plants of the late 19th century. Both

the Owens Bottle Machine Company of Toledo, Ohio, and Corning Glass

of Corning, New York, were conducting experiments to make glass wool in their

bottle plants, without great success. Then, during an attempt to weld together

blocks of glass, a jet of compressed air accidentally struck a stream of molten

glass, resulting in fine glass fibers and the birth of fiberglass.

In 1935, realizing the potential growth of the glass

fiber insulation market, Corning Glass approached the then-named Owens-Illinois

Glass Company with a proposal to join forces in the production of glass

fiber. Recognizing the benefit of Corning's knowledge of glass formulations,

Owens-Illinois agreed to the proposal, forming the Owens-Corning Fiberglas

Corporation in 1938 as a joint venture.

In 1938, the new company opened its first research

and manufacturing operation in Newark, Ohio, with 543 employees, where it

produced a fiberglass glass air filter that quickly became a standard

component of most forced-air furnaces.

During World War II, Owens Corning plants ran at capacity,

creating increasingly important insulation for warships, as well as glass fiber

laminate, used by the U.S. Air Force for structural aircraft parts. To meet

demand, the company's wartime employment level rose to nearly 6,400 people,

pushing 1944 sales to $\$58,499,000$.

Following the War, Owens Corning explored dozens of new

applications for glass fiber and glass fiber laminates, including pleasure

boats, fishing rods, acoustical tile and even automobiles, with the first Corvette.

The celebrated fame of "fiberglass chair" of 1947 was the

first product made of pre-formed glass fiber.

In 1952, with sales of over $\$97$ million, Owens

Corning made its initial public offering on the New York Stock Exchange, as the

company began a global expansion into Mexico, Japan and Australia. The

trademarked PINK Fiberglass insulation emerged in 1956, when the company

added red dye to its newest "Air Fiber" insulation product to

distinguish it from earlier standard products.

The 1960s brought continued expansion into Europe,

Latin America, Africa and Asia Pacific, as well as new product lines. Sales

surpassed $\$500$ million for the first time in 1971 as new roofing

applications for glass fiber materials were developed. By 1976, sales topped $\$1$

billion. The "Pink Panther" cartoon character became a

company icon in 1980 and in 1987 Owens Corning became the first and only

company to trademark a color - PINK. In 1994, Owens Corning again made

glass fiber history with the development of resilient Miraflex$^{\text{TM}}$

fiber, the first new form of glass fiber in nearly 60 years.

Today, Owens Corning is a $3.8 billion business, held

publicly, composed of 19,000 people with manufacturing, sales and research

facilities, including joint venture and licensee relationships, in more than 30

countries worldwide. From from a small filament of glass, the company now

offers a diversified array of products, including complete building

materials systems; advanced glass fiber used in more than 40,000

composite end-use applications from skis and golf clubs, to bridge decking and

transmission towers, to automobiles, computers, and fiber-optic cables; and

large diameter pipe used to build the infrastructure of developing nations.

Corporate Milestones

1938: Owens-Corning Fiberglas Corporation is

formed. Ownership is equally divided between Owens-Illinois Glass Company and

Corning Glass Works. Company introduces Fiberglas insulation and furnace

filters.

1940: Fiberglas Canada, Ltd., is established.

Owens Corning is a principal owner.

1950s: Owens Corning provides technical support to

Chevrolet in development of the first Corvette auto body of glass fiber

reinforced plastic. Continuous strand fiber and yarns, two early glass

fiber materials for composite applications, are introduced.

1952: Owens Corning is listed on the New York

Stock Exchange, with one-third ownership by the public, and one-third each

by Owens-Illinois and Corning Glass. (As of December 1996, neither company owns

shares of Owens Corning stock.)

1960s: Applications of reinforcements and glass fiber

reinforced plastic expand dramatically, including development of underground

tanks and pipe.

1970s: Owens Corning designs and manufactures an

insulation system for above-ground portions of the Trans-Alaska Pipeline and

assists in development of glass fiber reinforced radial tire.

1976: Sales surpass $1 billion.

1977: Company enters residential roofing and

industrial asphalt business.

1979: Sales surpass $2 billion.

1980s: Major expansion of the company's Science &

Technology Center in Granville, Ohio. The Pink Panther is introduced in

advertising, helping to establish strong brand identification for Owens Corning

products.

1986: Shareholders approve a comprehensive

recapitalization and restructuring plan as an alternative to an unsolicited

takeover attempt.

1987: Owens Corning becomes the first and only

company to trademark a color - PINK - reflecting high consumer awareness

of the company's residential insulation products.

1989: Owens Corning acquires the remainder of

Fiberglas Canada.

1992: Under the leadership of new Chairman and CEO Glen

H. Hiner, Owens Corning introduces a new corporate mark and embarks on an

agenda of global growth.

1993: $5 billion sales target is set for the

year 2000 with earnings and cash flow growing at twice the rate of sales. Non-core

assets are divested, including a swap of the commercial roofing business

for a residential roofing business. The Asia Pacific division is created

and the company is listed on the Toronto Stock Exchange.

1994: Resilient Miraflex$^{\text{TM}}$ fiber —

the first new form of glass fiber in nearly 60 years — is introduced in its

first application, PinkRobe$^{\text{TM}}$ Plus featuring Miraflex$^{\text{TM}}$

fiber. The revolutionary Jackson composites plant is re-opened as a model for

future facilities. Acquisitions expand insulation capacity in Europe and

provide entry into the foam insulation business in the U.S.

1995: Owens Corning launches Advantage 2000,

its global systems reengineering initiative. Miraflex$^{\text{TM}}$ fiber is

recognized with awards for technological innovation. Completion of five niche

acquisitions in building materials, further expanding the company's product

offerings. Opening in China of first pipe plant and first insulation plant.

1996: The company changes its name to Owens

Corning, dropping the word Fiberglas, to better reflect the broad-based

diversity of its businesses. The New York Stock Exchange ticker symbol changes

to OWC. The company also announces that it will meet its $5 billion

sales goal in 1999, a full year ahead of schedule, and reinstates a

dividend policy (see pg. 70).

Owens Corning launches its company-wide business strategy, System

Thinking$^{\text{TM}}$ its first application, System Thinking for the

Home$^{\text{TM}}$, allows the company to leverage its leadership position

in the building materials industry by providing a cost effective,

high-performance envelope for the home. System Thinking$^{\text{TM}}$ for

Composites and Engineered Pipe Systems strategies are developed.

Corporate Structure

Owens Corning is organized into 10 businesses, each

responsible for operations and business development within a certain product,

system or market category or geographic region.

- Building

Materials Sales and Distribution — North America: Responsible for the

sale and distribution of building materials systems in North America to

retailers, distributors and contractors.

- Insulation:

Responsible for insulation contractors, development of insulating systems,

Miraflex$^{\text{TM}}$ fiber, commercial and mechanical insulation, and

insulation and fabrication plants in North America.

- Roofing/Asphalt:

Responsible for working with contractors, distributors and manufacturers

involved in the sale of residential roofing products or applications of

industrial asphalt. Also responsible for development of integrated roofing

systems, as well as for roofing and asphalt plants.

- Building

Materials — Europe and Africa: Responsible for the manufacture,

marketing and sale of the company's building materials in Europe and

Africa.

- Asia

Pacific: Responsible for all products and systems, as well as

operations and development of new growth opportunities in the Asia Pacific

region.

- Latin

America: Responsible for all products and systems, as well as

operations and development of new growth opportunities in the Latin

America region.

- Specialty

and Foam Products: Responsible for growing the company's PINK,

extruded polystyrene and expanded foam insulation and related products, as

well as window/patio door businesses, vinyl siding and housewrap, and

other products that continue to be added to leverage Owens Corning's brand

and distribution strengths.

- Western

Fiberglas Group: Responsible for the manufacture, sale and

distribution of glass fiber insulation, as well as development of small

furnace technology and expansion of small plant operations in developing

countries.

- Composites:

Responsible for the development, manufacture, marketing and sale of glass

fiber reinforcements used in composite materials globally.

- Engineered

Pipe Systems: Responsible for building the company's glass fiber

reinforced plastic pipe business around the world.

Corporate Units

Owens Corning operates a Science & Technology

organization responsible for overseeing the development of new products and

processes, engineering and environmental technology. In addition, five

corporate staff units support global operations:

- Business

Development/Planning/Sourcing, including strategic planning, global

sourcing, health and safety, and corporate communications;

- Law;

- Finance,

including taxes, accounting, information systems and investor relations;

- Human

Resources, including internal communications; and,

- Government

and Public Affairs.

Financial Reporting

For financial reporting purposes, financial results of Owens

Corning's businesses are grouped into two segments: Building Materials and

Composite Materials.

Glass Fiber for Composites Industry – Value Chains

|

Transportation (SMC Process) |

Electrical (Laminating Process) |

Construction (Pultrusion Process) |

|

Owens Corning Products |

||

|

Owens Corning glass fiber products are produced in various

forms, such as multi-end rovings, yarns and single-end rovings... |

\ |

\ |

|

Different Processes |

... glass is mixed with various materials like resins and

other additives and processed using processes such as sheet molding

compound (SMC), laminating and pultrusion... |

|

|

End-Use Applications |

... and into over 40 thousand end-use applications. |

|

|

Examples |

||

|

Automotive interiors and exteriors |

Printed circuit boards |

I-Beams |

|

Railcar components |

Electrical enclosures |

Utility poles |

|

Heavy truck panels |

Circuit breaker boxes |

Transmission towers |

|

ISO containers |

Cable reinforcements |

Rebar (concrete reinforcement) |

|

Ignition cables |

Electrical connectors |

Pre-stressed tendons |

|

Brake shoes |

Safety ladders |

Tensile members |

|

Manifolds |

Cables, etc. |

|

|

Mufflers |

||

|

Bumper beams |

||

Global Operations

|

World Headquarters |

Dallas, Texas |

Muncy, City, North Carolina |

|

United States |

Grand Rapids, Michigan |

Oklahoma City, Oklahoma |

|

Toledo, Ohio |

Houston, Ohio |

Portland, Oregon |

|

Johnson City, Tennessee |

Summit, Illinois |

|

|

Science & Technology Centers |

Laredo, Texas |

|

|

Belgium |

Los Angeles, California |

Windows: |

|

Battice |

Memphis, Tennessee |

United States |

|

United States |

Montgomery, Alabama |

Hazleton, Pennsylvania (lineals) |

|

Granville, Ohio |

Newark, New Jersey |

Martinsville, Virginia (fabrication) |

|

Orlando, Florida |

St. Louis, Missouri (fabrication) |

|

|

Manufacturing Facilities (wholly owned) |

Sacramento, California |

|

|

Thermal and Acoustical Insulation: |

Shelbyville, Kentucky (2) |

Composite Materials: |

|

Springfield, Tennessee |

||

|

Belgium |

Tiffin, Ohio |

Belgium |

|

Battice |

||

|

Battice |

Miraflex$^{\text{TM}}$ Fiber Plant: |

Brazil |

|

Vive |

United States |

Rio Claro |

|

Canada |

Mt. Vernon, Ohio |

Canada |

|

Candiac, Quebec |

Guelph, Ontario |

|

|

Edmonton, Alberta |

Roofing: |

France |

|

Scarborough, Ontario |

United States |

L'Ardoise |

|

United Kingdom |

Atlanta, Georgia |

The Netherlands |

|

Pontypridd, South Wales |

Brownsville, Indiana |

Apeldoorn |

|

Ravenscroft, North Wales (rockwool) |

Compton, California |

Norway |

|

Ravenhead, St. Helens, Great Britain |

Denver, Colorado |

Birkeland |

|

United States |

Houston, Texas |

Spain |

|

Delmar, New York |

Irving, Texas |

Sant Vicenc de Castellet/Barcelona |

|

Eloy, Arizona |

Jacksonville, Florida |

United Kingdom |

|

Fairburn, Georgia |

Jessup, Maryland |

Liversedge, Great Britain |

|

Kansas City, Kansas |

Kearny, New Jersey |

Wrexham, Great Britain |

|

Newark, Ohio |

Medford, Ohio |

United States |

|

Passaic, Texas |

Memphis, Tennessee |

Aiken, South Carolina |

|

Salt Lake City, Utah |

Minneapolis, Minnesota |

Amarillo, Texas |

|

Santa Clara, California |

Portland, Oregon |

Anderson, South Carolina |

|

Waxahachie, Texas |

Savannah, Georgia |

Fort Smith, Arkansas |

|

Summit, Illinois |

Huntington, Pennsylvania |

|

|

Foam Insulation & Related Products: |

Jackson, Tennessee |

|

|

United States |

Asphalt Processing: |

|

|

Byron Center, Michigan |

United States |

Pipe: |

|

Rockford, Illinois |

Atlanta, Georgia |

China |

|

Tallmadge, Ohio |

Channeltown, Texas |

Changchun |

|

Compton, California |

Norway |

|

|

Fabrication Centers: |

Denver, Colorado |

Sandefjord |

|

Canada |

Detroit, Michigan |

|

|

Brantford, Ontario |

Houston, Texas |

Manufacturing Alliances |

|

United States |

Irving, Texas |

United States |

|

Jacksonville, Florida |

Canton, Georgia |

|

|

Angola, Indiana |

Jessup, Maryland |

(AURA$^{\text{TM}}$ Superinsulation panels) |

|

Athens, Alabama |

Kearny, New Jersey |

|

|

Atlanta, Georgia |

Medford, Ohio |

|

|

Cleveland, Tennessee |

Memphis, Tennessee |

|

|

Columbus, Ohio |

Minneapolis, Minnesota |

Joint Ventures

|

Location |

Company Name (Ownership %) |

Established |

|

Argentina, Cordoba |

Owens-Corning Calsa, S.A. (pipe; 50% ownership) |

1995 |

|

Botswana, Gaborone |

Owens-Corning Pipe Botswana (proprietary) Ltd. (pipe; 49%

ownership) |

1992 |

|

China, Guangzhou |

Owens-Corning (Guangzhou) Fiberglas Co. Ltd. (insulation;

90% ownership) |

1994 |

|

China, Shanghai |

Owens-Corning (Shanghai) Fiberglas Co. Ltd. (insulation;

90% ownership) |

1995 |

|

China, Nanjing |

Owens-Corning (Jiangsu) XPS Pipe Co. Ltd. (PINK

FOAMULAR$^{\text{TM}}$ insulation; 51% ownership) |

1996 |

|

Colombia, Barbosa |

Owens-Corning Andercol Tuberias, S.A. (pipe; 50%

ownership) |

1996 |

|

Germany, Mochau |

Owens-Corning Eternit Rohre GmbH (pipe; 50% ownership) |

1993 |

|

Korea, Seoul |

LG Owens-Corning Corporation (composite materials; 31%

ownership) |

1989 |

|

Mexico, Mexico City |

Vitro Fibras S.A. (composite materials and insulation; 40%

ownership) |

1957 |

|

Saudi Arabia, Dammam |

Amiantit Fiberglass Industries Limited (pipe; 30%

ownership) |

1977 |

|

Saudi Arabia, Dammam |

Arabian Fiberglass Insulation Co. (insulation; 49%

ownership) |

1979 |

|

Spain, Camarles |

Owens-Corning Tubs, S.A. (pipe; 50% ownership) |

1994 |

|

Thailand, Bangkok |

Siam Fiberglas Co., Ltd. (pipe and insulation; 20%

ownership) |

1991 |

|

United States, Seguin, Texas |

Knytex Company, L.L.C. (composite materials; 50%

ownership) |

1993 |

|

United States, Collierville, Tennessee |

Alpha/Owens-Corning, L.L.C. (polyester resins; 50%

ownership) |

1994 |